First I cut it in half - the thickest end was very knotted so figured I would get the best spoons out of the top half.

Then I cut it into the individual sections I thought I could use for spoons - three crooks and a straight section.

Then with axe and beadle I split the sections into spoons blanks - I reckoned I could get 6 spoons of varying sizes and varieties. I was very pleased as I don't often get good crooks and so don't have a lot of experience of these types of spoons and was looking forward to making some. Needless to say, I got to work on my first laddle, only to find that, before I had even really roughed it out it had started to split! Damn!

|

| Obviously the handle would have been a lot slimmer, had I continued with it, but you can see the lovely shape it would have been. |

To makemyslef feel a little better I turned to some good old, trustworthy sycamore and carved a spreader and a nice little eating spoon. It went without a hitch, which is just the way I like it. I haven't carved a spreader in well over over a year (I have carved loads in the past) and fancied having a go with my new axe.

|

| These are the main wooden items we use at home - very handy for spreading and cooking with - my wife uses them instead of spatulas - perhaps I should make some of those as well. |

I found this brilliant book in a charity shop, which made my day.

It is a great old book, published in '68 - the year I was born - covering a wide range of traditional crafts. It doesn't go into too much detail - you would struggle to learn a craft from this book - but it gives a nice overview of each craft and its history and would be helpful if you already had some knowledge.

The chapters are as follows:

Woodland and Coppice Industries

Felling

Conversion

Pit Sawing

Making Gates and Wattle Hurdles

Making Walking Sticks

Making Rakes, Scythe-snaiths, Forks

Making Helves, Yokes, Shovels, Peels and Flails

Making Besoms

Making Fencing, Clapboards and Shingles

Making Clogs

Charcoal-burning

Carpentry

Chair-bodging

Making Windsor Chairs

Farriery

Wrought-iron Work

Wheelwrighting

Millwrighting

Thatching

Wood-carving

Wood-turning

Weaving

Bow-and-arrow Making

Making Coracles

Pottery

Hedge-laying

Dry-stone Walling

Making Baskets and Traps

Saddlery and Harness-making

Horn-work

Making Corn-dollies

Flint-knapping

Coopering

Pillow-lace Making

Quilting

Making Highland Bagpipes

Timber

Making Briar-pipes

Further Reading

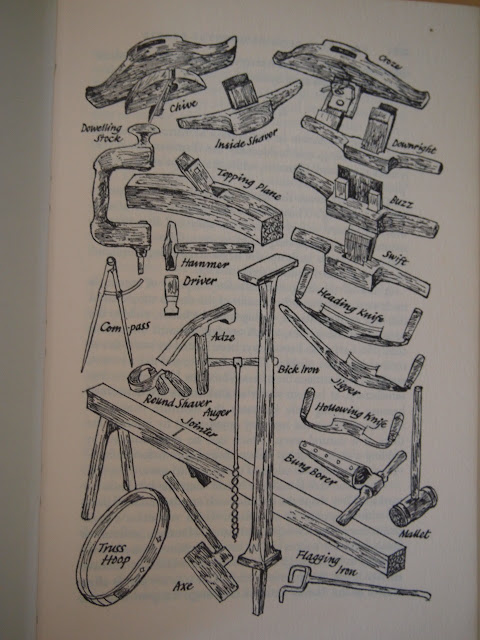

Quite a collection of crafts and skills. And I love the illustrations - here are just a few:

|

| Coopering tools |

I look forward to seeing if Ican track down some of the books in the Further Reading section.

While I know this is something of a contentious issue, I thought I would just include the opening paragraphs of the chapter entitled 'Craftsmanship' under the side heading 'Definitions':

"What is a craftsman? He or she who, broadly speaking, makes things individually by hand, using only such tools and appliences which are manipulated. With a few exceptions, these tools are quite simple in themselves, and in many cases are little more than perfections of the original tool of centuries ago. A craftsman is usually the designer of the thing he is making, but in some practices there may be a mutual division of operations, though not tothe extent that one person is isolated from the other or is not concerned with what the other is doing. In fact, an important feature is the close co-operation.

A craftsman may be an individaul working alone, such as a hedge-layer, or he may be one of a team or a unit, such as a wheelwright. Where design and execution do happen to be divided between two or more persons, there must be the closest co-operation. The situation whereby the designer and the executant do not meet is unknown.

A craftsman makes things by hand, one at a time, and can therefore impart an individuality in each product according to his or her own will. In fact, with certain exceptions, one may fairly say that 'no two are alike'."